Artificial Turf

High-Performance Artificial Turf Systems

We deliver FIFA, World Rugby and other compliant artificial turf systems designed around performance, longevity and local climate. From dynamic bases to engineered shockpads and advanced infills, every layer is specified to achieve consistent ball roll, rotational resistance and player comfort.

Our build process controls drainage, planarity and seam integrity—so the surface plays fast, feels safe and looks elite across its lifecycle.

*Indicative; usage depends on sport code, climate and maintenance.

Why Choose Our Turf Systems

Consistent Playability

Stable ball pace and rebound with certified rotational resistance.

All-Weather Availability

Fast draining base & profile ensures minimal downtime after rainfall.

Player Comfort & Safety

Shockpads tuned for force reduction, energy restitution and HIC.

Durability & UV Stability

High-tenacity yarns with quality backing and robust seam detailing.

Lower Lifecycle Cost

Efficient grooming plan and predictable renewal path.

Multi-Sport Options

Football, rugby, hockey lines and inlays integrated cleanly.

System Build (Top to Base)

- Turf Carpet – monofilament/SLITF yarns, tufted, with robust primary/secondary backing.

- Performance Infill – TPE/EPDM or approved alternatives, calibrated for force reduction & energy restitution.

- Stabilising Sand – graded silica sand to stabilise pile and control ball roll.

- Shockpad / Elastic Layer – pre-fabricated pad or in-situ e-layer to tune impact performance.

- Base Layer – open-graded asphalt or engineered dynamic stone base, laser-trimmed.

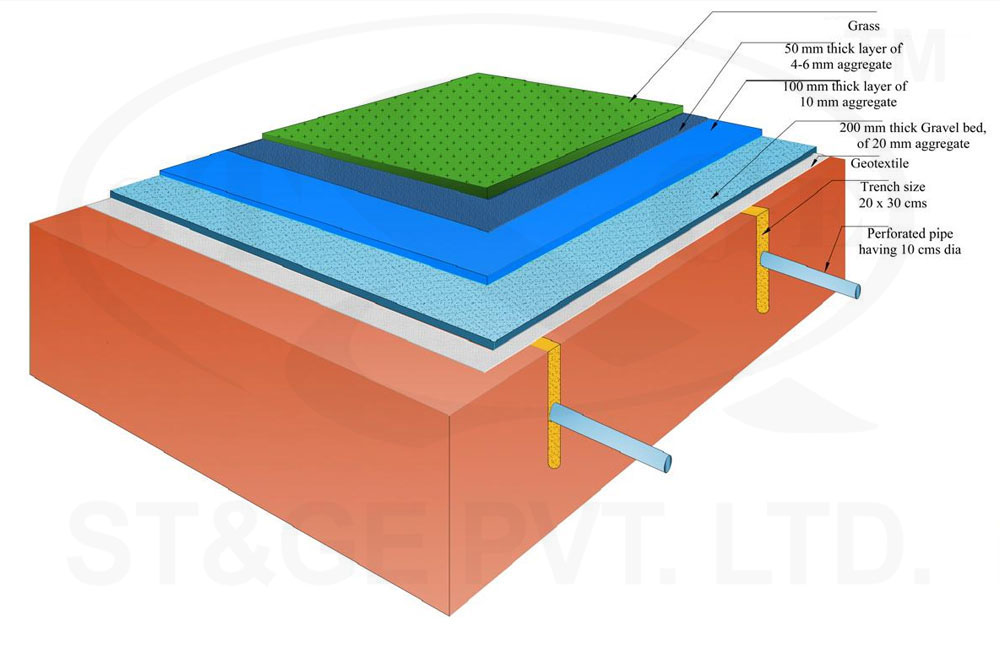

- Sub-Base & Drainage – free-draining aggregate with laterals/collectors per design.

Our Construction Workflow

-

01 Survey, design & benchmarks at site -

02 Earthworks, formation trimming & compaction -

03 Sub-base prep and shaping at site -

04 Modern sub-surface drainage -

05 Base installation option - dynamic stone -

06 Base installation option - asphalt -

07 Shockpad / elastic layer installation -

08 Turf carpet lay & seaming across the field -

09 Inlay lines & markings across the field -

10 Infill placement on the artificial turf -

11 Installation & Testing of Irrigation system -

12 Testing, handover & maintenance briefing

Maintenance Programme

A structured grooming plan preserves performance and extends service life:

- Routine brushing, decompaction & infill redistribution

- Debris removal and contamination control

- Seam/edge inspections & prompt repairs

- Annual deep clean and infill top-up as required

- Periodic lab/field tests against compliance targets

Performance & QA

Key Metrics

- Ball roll & rebound

- Rotational resistance & traction

- Shock absorption & vertical deformation

- Planarity & infill depth uniformity

Handover

- Tolerance checks: grade, evenness, seams

- Certification testing as required (FIFA/WR/FIH)

- O&M manual + training

- Post-handover support