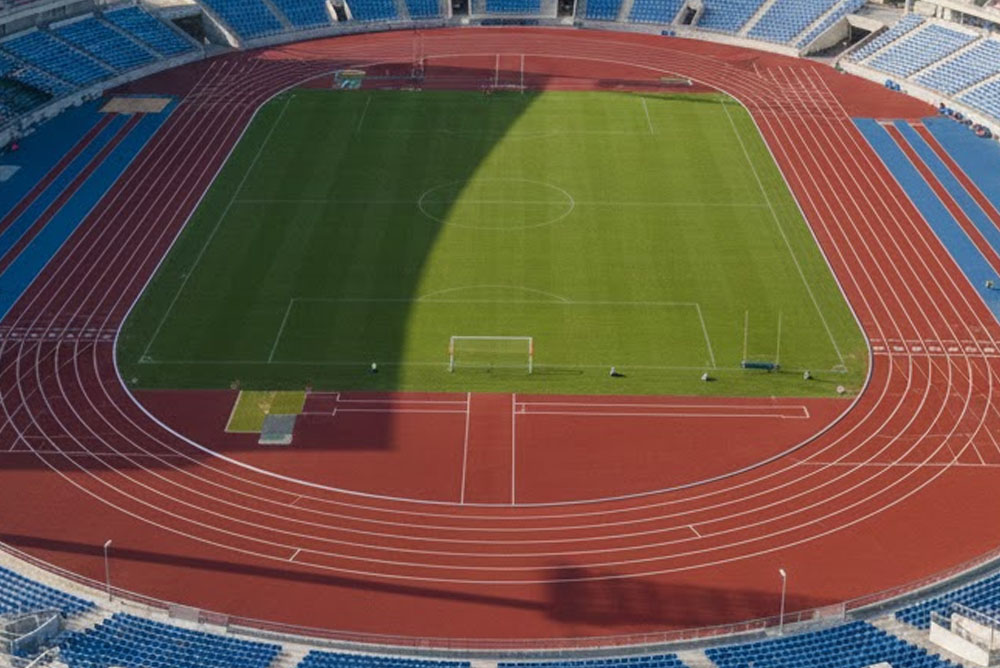

Athletic Tracks

World-Class Track Systems, Engineered for Speed

We design and build athletic tracks that meet World Athletics standards for speed, resilience and safety. From sub-base preparation to the final coloured wear layer, every step is controlled to deliver consistent force reduction, vertical deformation and friction.

Systems include in-situ elastomer layers, prefabricated sheets, or hybrid builds—specified for your climate, events calendar and budget.

*Target range depends on system selection and certification class.

Why Our Tracks Perform

Certified Performance

Designed for World Athletics testing: force reduction, deformation, friction.

Speed & Traction

Optimised surface energy return and macro/micro-texture for grip.

Durability

UV-stable binders, calibrated EPDM and robust detailing for long service life.

Drainage & Base Integrity

Engineered base and falls to manage water and protect layers.

Clear Marking

High-contrast lines and event markings with precise geometry.

Lifecycle Value

Maintainable top coats, patch repair strategies and predictable re-top cycles.

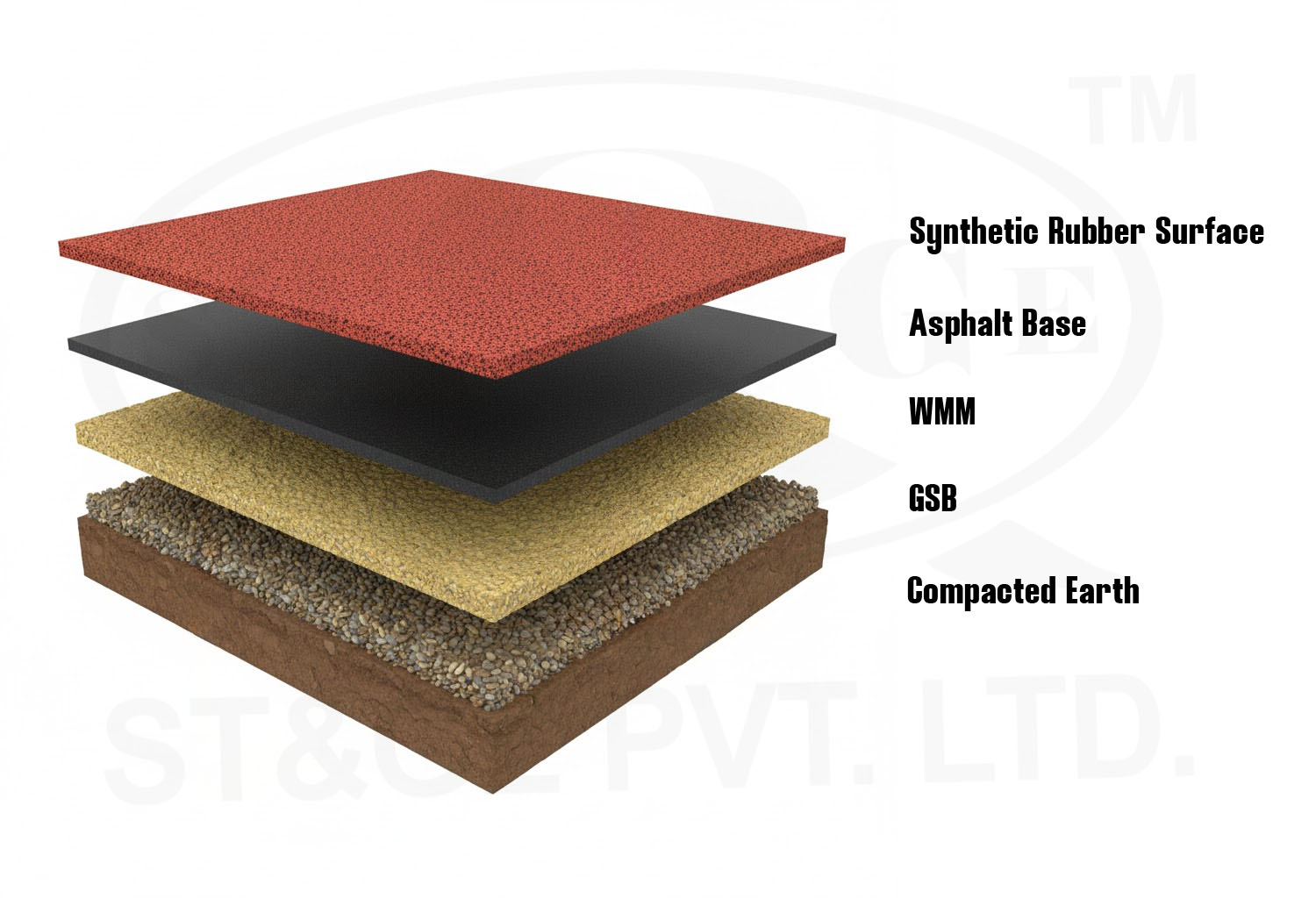

System Build (Surface to Sub-Base)

- Synthetic Rubber Surface: Coloured PU-bonded EPDM granules providing texture, grip, and weather-resistant performance for running tracks.

- Asphalt Base: Precision-graded asphalt layer delivering stability, smoothness, and long-term durability for the athletic surface.

- WMM (Wet Mix Macadam): Load-bearing structural layer offering uniform support and strength beneath the asphalt.

- GSB (Granular Sub Base): Free-draining granular layer engineered for foundational stability and effective water management.

- Compacted Earth: Well-compacted formation layer trimmed to required levels and slopes to support the full system.

Event areas (jumps, throws) receive tailored detailing for take-off boards, sand pits, cages and gutters.

Our Construction Workflow

-

01 Survey, base testing & design at site -

02 Earthworks, formation trimming & compaction -

03 Subgrade prep, falls & compaction -

04 Drainage install & edge details -

05 Base Course - 1st layer - GSB on the surface -

06 Base Course - 2nd layer - WMM on the surface -

07 Asphalt Base - 1st layer - BM on the surface -

08 Asphalt Base - 2nd layer - BC on the surface -

09 Primer Layer installation on the surface -

10 Wear layer application (PU + SBR) -

11 Wear layer application (PU + EPDM) -

12 Lane & event line marking as per requirement

Maintenance Programme

Planned care preserves grip, colour and performance:

- Regular surface cleaning and debris removal

- Algae/moss control where required

- Joint/seam inspections and repairs

- Periodic re-texturing or recoating plan

- Compliance checks for force reduction & friction

Performance & QA

Key Metrics

- Force reduction & vertical deformation

- Friction / slip resistance (wet & dry)

- Planarity & thickness uniformity

- Colour/texture uniformity

Handover

- Tolerance checks: geometry, lane widths, radii

- Certification testing (as required)

- O&M manual + training

- Post-handover support