Synthetic Pitch

High-Use Synthetic Pitches with Certified Performance

We build synthetic pitches engineered around usage hours, compliance and local climate. Systems are specified end-to-end—base design, shock attenuation, carpet & infill—so you get predictable ball roll, traction and comfort with low downtime.

Our construction controls planarity, seams and drainage. The result is a fast, consistent surface that meets FIH targets throughout its lifecycle.

*Indicative; depends on sport code, climate and maintenance.

Why Choose Our Synthetic Systems

All-Weather Availability

Fast drainage & resilient profile for minimal downtime.

Certified Playability

Ball roll, traction and rotational resistance within target bands.

Player Comfort & Safety

Shockpads tuned for force reduction and deformation.

Long Service Life

UV-stable yarns, robust backings, quality seam construction.

Operational Efficiency

Low routine maintenance and predictable renewal path.

Multi-Sport Ready

Clean inlays and markings for football, rugby, and more.

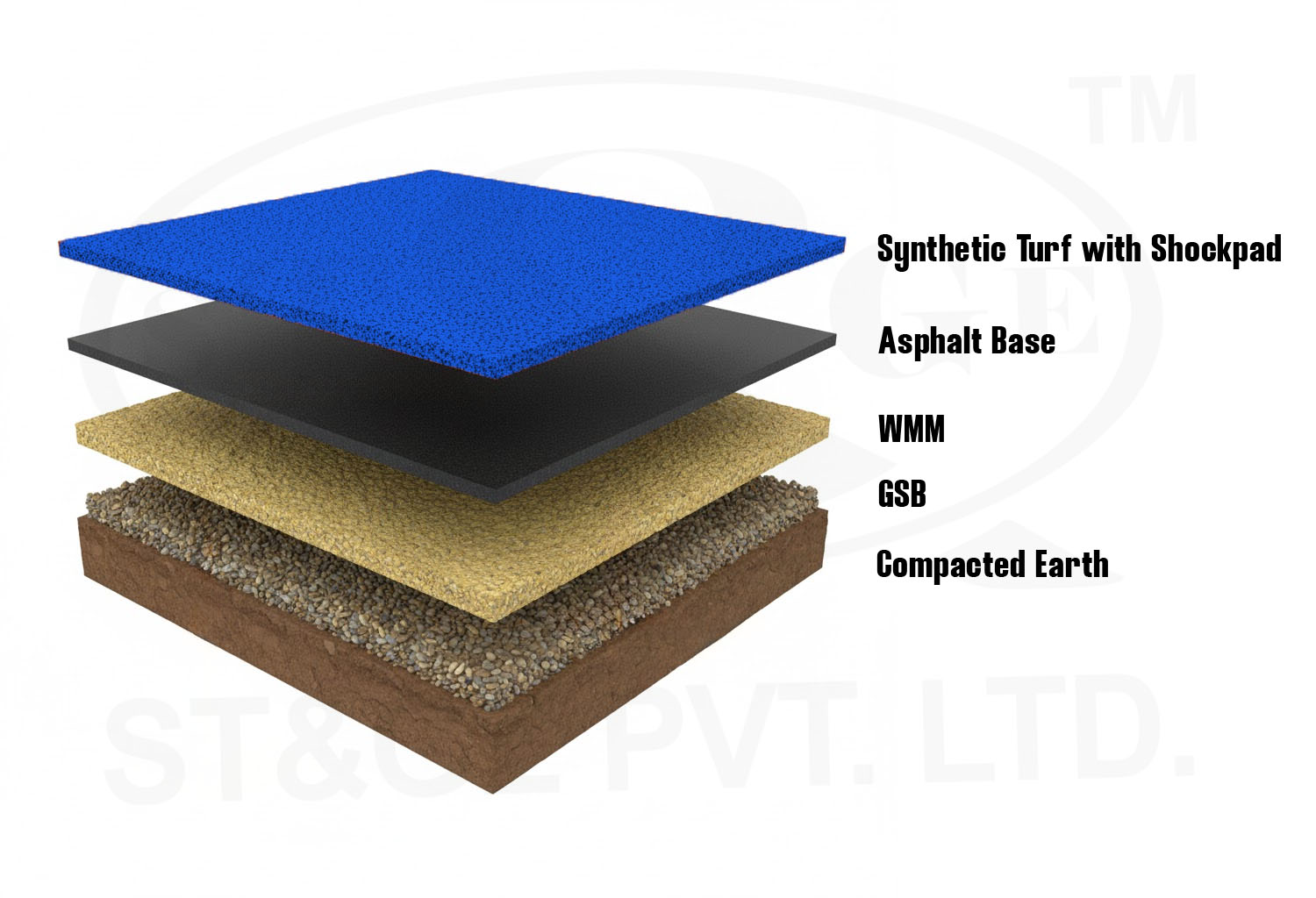

System Build (Top to Base)

- Synthetic Turf with Shockpad: integrated turf system featuring monofilament/hybrid yarns and an in-built prefabricated shockpad layer for player-safety and performance consistency.

- Asphalt Base: laser-graded open-graded asphalt layer providing a stable, smooth, and durable platform for the turf system.

- WMM (Wet Mix Macadam): dense, load-bearing base course providing structural strength and uniform support beneath the asphalt.

- GSB (Granular Sub Base): free-draining granular layer that facilitates water movement and provides foundational stability.

- Compacted Earth: well-compacted and trimmed formation layer prepared to the required design levels and slopes.

Our Construction Workflow

-

01 Survey, design & benchmarks at site -

02 Earthworks, formation trimming & compaction -

03 Sub-base prep and shaping at site -

04 Base course installation - GSB -

05 Base course installation - WMM -

06 Top course installation - BM/BC -

07 Shockpad / elastic layer installation -

08 Turf carpet lay & seaming across the field -

09 Inlay lines & markings across the field -

10 Installation & Testing of Irrigation system -

11 Installation of dugouts, goalposts etc. -

12 Testing, handover & maintenance briefing

Maintenance Programme

A structured care plan preserves compliance and playability:

- Regular brushing and decompaction

- Infill redistribution and depth checks

- Seam & edge inspections; prompt repairs

- Annual deep clean; infill top-ups

- Periodic lab/field tests vs targets

Performance & QA

Key Metrics

- Ball roll & rebound

- Rotational resistance & traction

- Shock absorption & vertical deformation

- Planarity & infill uniformity

Handover

- Tolerance checks: evenness, seams, lines

- Certification testing as required

- O&M manual + training

- Post-handover support